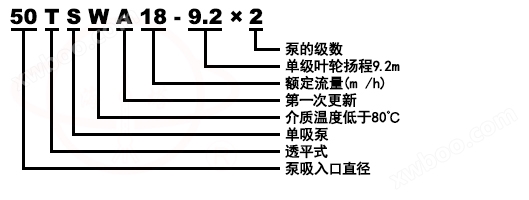

Model Meaning

Product Introduction

TSWA horizontal low-speed centrifugal multi-stage pump is used to transport clean water without solid particles and liquids with physical and chemical properties similar to water.

Mainly used for high-pressure water supply, high-rise building water supply, and can also be used for factory and mine water supply and drainage.

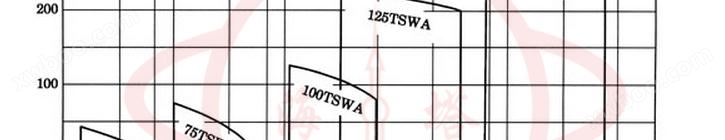

The flow rate of the pump ranges from 10~155 m3/h, the head range is 15~300m, the matching power range is 2.2~200kw, and the diameter range is 50~150mm.

The operating temperature of TSWA type medium shall not exceed 80 ℃.

Product Features

1. TSWA horizontal clear water low-speed centrifugal multi-stage pump has a compact structure, small volume, beautiful appearance, small footprint, and saves construction costs;

2. The rotor components of the TSWA horizontal low-speed centrifugal multi-stage pump for clean water are supported by rolling bearings at both ends, ensuring smooth operation of the pump;

3. The inlet of TSWA horizontal low-speed centrifugal multi-stage pump for clean water is arranged horizontally, and the outlet is arranged vertically upwards to simplify the pipeline;

4. The motor of TSWA horizontal low-speed centrifugal multi-stage pump for clean water is a horizontal structure, which is easy to maintain.

application

Mainly used for high-rise building domestic water supply, fire constant pressure water supply, automatic sprinkler water supply, automatic water curtain water supply, etc., it can also be applied to factory and mine water supply and drainage, long-distance water supply, various equipment matching use, and various production process water supply.

Conditions of Use

1. Suitable for transporting clean water and substances with physical and chemical properties similar to clean water, with a solid insoluble volume not exceeding 0.1% per unit volume and a particle size ≤ 2mm

2. Medium temperature: -15 ℃~80 ℃;

3. Work pressure: System pressure ≤ 3.0MPa; (i.e. system pressure=inlet pressure+pressure during pump operation ≤ 3.0MPa)

4. The ambient temperature should be below 40 ℃ and the relative humidity should be below 95%;

5. Due to the fact that the main components of this pump are made of cast iron, the medium it transports should not have strong corrosiveness.

If the medium contains small particles or has strong corrosiveness, please specify it when ordering to provide more reliable products.

STRUCTURE DESCRIPTION

1. The TSWA horizontal low-speed centrifugal multi-stage pump for clean water is a multi-stage segmented structure, with a horizontal suction inlet and a vertically upward discharge outlet. It is equipped with diameters of 50, 75, 100, 125, 150, etc. Users can choose pumps of different diameters and stages according to their flow rate and head requirements to achieve satisfaction;

2. The TSWA horizontal low-speed centrifugal multi-stage pump for clean water mainly consists of inlet section, middle section, guide vanes, impellers, outlet section, bearing body components, sealing components, etc. Its structural design is reasonable;

3. The rotor components of the TSWA horizontal low-speed centrifugal multi-stage pump for clean water are composed of a medium carbon steel shaft, cast iron impeller, balance disk, and shaft sleeve. The rotor is supported at both ends on dry oil lubricated rolling bearings. Due to the excellent dynamic and static balance of the impeller and the hydraulic balance of the balance disk, the pump operates smoothly with low noise and vibration.

4. The joint surfaces of the inlet, middle, and outlet sections are sealed by using paper pads and tightening bolts. To prevent liquid leakage from both ends of the main shaft, a soft packing shaft seal is installed. At the same time, a rubber water stop ring and an O-ring are installed on the shaft to prevent water from entering the shaft sleeve cavity;

5. To prevent wear of the middle section and guide vanes, vulnerable parts such as impeller sealing rings and guide vane sleeves are specially designed. When the gap between the impeller and these vulnerable parts exceeds the specified value, they should be replaced;

6. The TSWA horizontal low-speed centrifugal multi-stage pump for clean water is installed on a common cast iron base together with an electric motor, and its torque is transmitted through an elastic coupling.

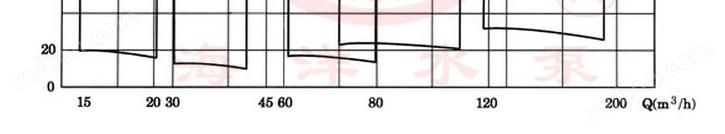

Structure diagram

|

|||||||||||

Serial Number |

name |

material |

Serial Number |

name |

material |

Serial Number |

name |

material |

Serial Number |

name |

material |

1 |

coupling |

HT200 |

7 |

Guide vane |

HT200 |

13 |

balance disc |

HT200 |

19 |

Right bearing cover |

HT200 |

2 |

Left bearing pressure cap |

HT200 |

8 |

middle |

HT200 |

14 |

Packing body |

HT200 |

20 |

Left bearing pressure cap |

Q235 |

3 |

Left bearing seat |

HT200 |

9 |

Final guide vane |

HT200 |

15 |

Right bearing seat |

HT200 |

21 |

bearing |

Bronze |

4 |

Left packing gland |

HT200 |

10 |

Water outlet section |

HT200 |

16 |

Right packing gland |

HT200 |

22 |

Left bearing liner |

Q235 |

5 |

Inlet section |

HT200 |

11 |

Balanced section |

HT200 |

17 |

Right packing shaft sleeve |

Q235 |

23 |

Left packing shaft sleeve |

Q235 |

6 |

impeller |

HT200 |

12 |

Balance ring |

HT200 |

18 |

Right bearing liner |

Q235 |

24 |

axle |

45 or 2Cr13 |

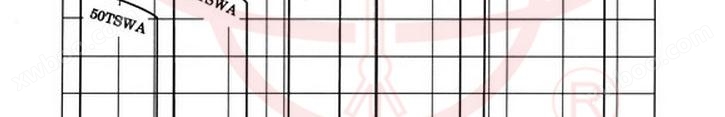

Spectrogram

|

performance parameter

model |

series |

internet traffic |

lift |

rotational speed |

Power (kw) |

efficiency |

permitted suction vacuum lift |

npsh |

weight |

||

m3/h |

L/S |

m |

r/min |

shaft power |

Motor Power |

% |

m |

m |

kg |

||

50TSWA18-9.2*2 |

2 |

18 |

5 |

18.4 |

1450 |

1.37 |

2.2 |

66 |

7.2 |

3.1 |

135 |

50TSWA18-9.2*3 |

3 |

18 |

5 |

27.6 |

1450 |

2.05 |

3 |

66 |

7.2 |

3.1 |

155 |

50TSWA18-9.2*4 |

4 |

18 |

5 |

36.8 |

1450 |

2.73 |

4 |

66 |

7.2 |

3.1 |

175 |

50TSWA18-9.2*5 |

5 |

18 |

5 |

46 |

1450 |

3.42 |

5.5 |

66 |

7.2 |

3.1 |

195 |

50TSWA18-9.2*6 |

6 |

18 |

5 |

55.2 |

1450 |

4.1 |

5.5 |

66 |

7.2 |

3.1 |

215 |

50TSWA18-9.2*7 |

7 |

18 |

5 |

64.4 |

1450 |

4.79 |

7.5 |

66 |

7.2 |

3.1 |

235 |

50TSWA18-9.2*8 |

8 |

18 |

5 |

73.6 |

1450 |

5.47 |

7.5 |

66 |

7.2 |

3.1 |

155 |

50TSWA18-9.2*9 |

9 |

18 |

5 |

82.8 |

1450 |

6.15 |

7.5 |

66 |

7.2 |

3.1 |

275 |

50TSWA18-9.2*10 |

10 |

18 |

5 |

92 |

1450 |

6.84 |

11 |

66 |

7.2 |

3.1 |

295 |

50TSWA18-9.2*11 |

11 |

18 |

5 |

101.2 |

1450 |

7.52 |

11 |

66 |

7.2 |

3.1 |

315 |

50TSWA18-9.2*12 |

12 |

18 |

5 |

110.4 |

1450 |

8.2 |

11 |

66 |

7.2 |

3.1 |

335 |

model |

series |

internet traffic |

lift |

rotational speed |

Power (kw) |

efficiency |

permitted suction vacuum lift |

npsh |

weight |

||

m3/h |

L/S |

m |

r/min |

shaft power |

Motor Power |

% |

m |

m |

kg |

||

75TSWA36-11.5*2 |

2 |

36 |

10 |

23 |

1450 |

3.22 |

5.5 |

70 |

7.2 |

3 |

|

75TSWA36-11.5*3 |

3 |

36 |

10 |

34.5 |

1450 |

4.83 |

7.5 |

70 |

7.2 |

3 |

|

75TSWA36-11.5*4 |

4 |

36 |

10 |

46 |

1450 |

6.45 |

11 |

70 |

7.2 |

3 |

|

75TSWA36-11.5*5 |

5 |

36 |

10 |

57.5 |

1450 |

8.06 |

11 |

70 |

7.2 |

3 |

|

75TSWA36-11.5*6 |

6 |

36 |

10 |

69 |

1450 |

9.67 |

15 |

70 |

7.2 |

3 |

|

75TSWA36-11.5*7 |

7 |

36 |

10 |

80.5 |

1450 |

11.28 |

15 |

70 |

7.2 |

3 |

|

75TSWA36-11.5*8 |

8 |

36 |

10 |

92.5 |

1450 |

12.89 |

18.5 |

70 |

7.2 |

3 |

|

75TSWA36-11.5*9 |

9 |

36 |

10 |

103.5 |

1450 |

14.5 |

18.5 |

70 |

7.2 |

3 |

|

75TSWA36-11.5*10 |

10 |

36 |

10 |

115 |

1450 |

16.12 |

22 |

70 |

7.2 |

3 |

|

75TSWA36-11.5*11 |

11 |

36 |

10 |

126.5 |

1450 |

17.73 |

22 |

70 |

7.2 |

3 |

|

model |

series |

internet traffic |

lift |

rotational speed |

Power (kw) |

efficiency |

permitted suction vacuum lift |

npsh |

weight |

||

m3/h |

L/S |

m |

r/min |

shaft power |

Motor Power |

% |

m |

m |

kg |

||

100TSWA69-15.6*2 |

2 |

69 |

19.2 |

31.2 |

1450 |

8.03 |

11 |

73 |

7 |

3.3 |

|

100TSWA69-15.6*3 |

3 |

69 |

19.2 |

46.8 |

1450 |

12.05 |

15 |

73 |

7 |

3.3 |

|

100TSWA69-15.6*4 |

4 |

69 |

19.2 |

62.4 |

1450 |

16.07 |

22 |

73 |

7 |

3.3 |

|

100TSWA69-15.6*5 |

5 |

69 |

19.2 |

78 |

1450 |

20.09 |

30 |

73 |

7 |

3.3 |

|

100TSWA69-15.6*6 |

6 |

69 |

19.2 |

93.6 |

1450 |

24.11 |

30 |

73 |

7 |

3.3 |

|

100TSWA69-15.6*7 |

7 |

69 |

19.2 |

109.1 |

1450 |

28.13 |

37 |

73 |

7 |

3.3 |

|

100TSWA69-15.6*8 |

8 |

69 |

19.2 |

124.8 |

1450 |

32.14 |

45 |

73 |

7 |

3.3 |

|

100TSWA69-15.6*9 |

9 |

69 |

19.2 |

140.4 |

1450 |

36.16 |

45 |

73 |

7 |

3.3 |

|

100TSWA69-15.6*10 |

10 |

69 |

19.2 |

156 |

1450 |

40.18 |

55 |

73 |

7 |

3.3 |

|

model |

series |

internet traffic |

lift |

rotational speed |

Power (kw) |

efficiency |

permitted suction vacuum lift |

npsh |

weight |

||

m3/h |

L/S |

m |

r/min |

shaft power |

Motor Power |

% |

m |

m |

kg |

||

125TSWA90-21.6*2 |

2 |

90 |

25 |

43.2 |

1450 |

14.32 |

22 |

74 |

6.8 |

3.4 |

|

125TSWA90-21.6*3 |

3 |

90 |

25 |

64.8 |

1450 |

21.48 |

30 |

74 |

6.8 |

3.4 |

|

125TSWA90-21.6*4 |

4 |

90 |

25 |

86.4 |

1450 |

28.63 |

45 |

74 |

6.8 |

3.4 |

|

125TSWA90-21.6*5 |

5 |

90 |

25 |

108 |

1450 |

35.79 |

55 |

74 |

6.8 |

3.4 |

|

125TSWA90-21.6*6 |

6 |

90 |

25 |

129.6 |

1450 |

42.95 |

75 |

74 |

6.8 |

3.4 |

|

125TSWA90-21.6*7 |

7 |

90 |

25 |

151.2 |

1450 |

50.11 |

75 |

74 |

6.8 |

3.4 |

|

125TSWA90-21.6*8 |

8 |

90 |

25 |

172.8 |

1450 |

57.27 |

90 |

74 |

6.8 |

3.4 |

|

125TSWA90-21.6*9 |

9 |

90 |

25 |

194.4 |

1450 |

64.43 |

90 |

74 |

6.8 |

3.4 |

|

125TSWA90-21.6*10 |

10 |

90 |

25 |

216 |

1450 |

71.59 |

90 |

74 |

6.8 |

3.4 |

|

model |

series |

internet traffic |

lift |

rotational speed |

Power (kw) |

efficiency |

permitted suction vacuum lift |

npsh |

weight |

||

m3/h |

L/S |

m |

r/min |

shaft power |

Motor Power |

% |

m |

m |

kg |

||

150TSWA155-30*2 |

2 |

155 |

43 |

60 |

1450 |

32.91 |

45 |

77 |

7.7 |

2.5 |

|

150TSWA155-30*3 |

3 |

155 |

43 |

90 |

1450 |

49.37 |

75 |

77 |

7.7 |

2.5 |

|

150TSWA155-30*4 |

4 |

155 |

43 |

120 |

1450 |

65.82 |

90 |

77 |

7.7 |

2.5 |

|

150TSWA155-30*5 |

5 |

155 |

43 |

150 |

1450 |

82.28 |

110 |

77 |

7.7 |

2.5 |

|

150TSWA155-30*6 |

6 |

155 |

43 |

180 |

1450 |

98.74 |

132 |

77 |

7.7 |

2.5 |

|

150TSWA155-30*7 |

7 |

155 |

43 |

210 |

1450 |

115.19 |

132 |

77 |

7.7 |

2.5 |

|

150TSWA155-30*8 |

8 |

155 |

43 |

240 |

1450 |

131.19 |

160 |

77 |

7.7 |

2.5 |

|

150TSWA155-30*9 |

9 |

155 |

43 |

270 |

1450 |

148.1 |

200 |

77 |

7.7 |

2.5 |

|

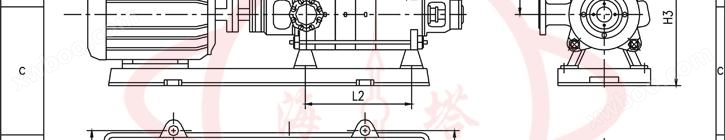

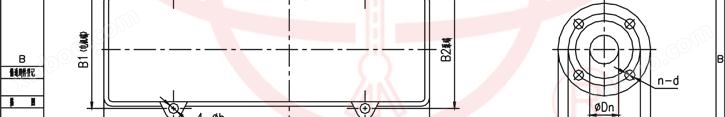

Installation size

|

|||||||||||||||||||||

model |

series |

Pump size (H2=B) |

Foot size |

Import and export flanges |

|||||||||||||||||

L |

L1 |

L2 |

B |

H3 |

L3 |

L4 |

L5 |

B1 |

B2 |

4-φb |

D |

D1 |

Dn |

n-φd |

|||||||

50TSWA18-9.2*2 |

2 |

1087 |

160 |

145 |

230 |

480 |

901 |

600 |

33 |

335 |

430 |

4-φ25 |

160 |

125 |

50 |

4-φ18 |

|||||

50TSWA18-9.2*3 |

3 |

1152 |

225 |

210 |

230 |

480 |

901 |

600 |

33 |

335 |

430 |

4-φ25 |

160 |

125 |

50 |

4-φ18 |

|||||

50TSWA18-9.2*4 |

4 |

1237 |

290 |

275 |

230 |

480 |

974 |

640 |

128 |

375 |

430 |

4-φ25 |

160 |

125 |

50 |

4-φ18 |

|||||

50TSWA18-9.2*5 |

5 |

1377 |

355 |

340 |

230 |

490 |

1153 |

740 |

132 |

430 |

430 |

4-φ25 |

160 |

125 |

50 |

4-φ18 |

|||||

50TSWA18-9.2*6 |

6 |

1442 |

420 |

405 |

230 |

490 |

1153 |

740 |

197 |

430 |

430 |

4-φ25 |

160 |

125 |

50 |

4-φ18 |

|||||

50TSWA18-9.2*7 |

7 |

1547 |

485 |

470 |

230 |

490 |

1321 |

840 |

197 |

430 |

430 |

4-φ25 |

160 |

125 |

50 |

4-φ18 |

|||||

50TSWA18-9.2*8 |

8 |

1612 |

550 |

535 |

230 |

490 |

1321 |

840 |

262 |

430 |

430 |

4-φ25 |

160 |

125 |

50 |

4-φ18 |

|||||

50TSWA18-9.2*9 |

9 |

1677 |

615 |

600 |

230 |

490 |

1386 |

860 |

297 |

430 |

430 |

4-φ25 |

160 |

125 |

50 |

4-φ18 |

|||||

50TSWA18-9.2*10 |

10 |

1827 |

680 |

665 |

230 |

490 |

1593 |

900 |

362 |

430 |

430 |

4-φ25 |

160 |

125 |

50 |

4-φ18 |

|||||

50TSWA18-9.2*11 |

11 |

1930 |

745 |

730 |

230 |

490 |

1593 |

1000 |

427 |

430 |

430 |

4-φ25 |

160 |

125 |

50 |

4-φ18 |

|||||

50TSWA18-9.2*12 |

12 |

1957 |

810 |

795 |

230 |

490 |

1658 |

1200 |

462 |

430 |

430 |

4-φ25 |

160 |

125 |

50 |

4-φ18 |

|||||

model |

series |

Pump size (H2=B) |

Foot size |

Import and export flanges |

|||||||||||||||||

L |

L1 |

L2 |

B |

H3 |

L3 |

L4 |

L5 |

B1 |

B2 |

4-φb |

D |

D1 |

Dn |

n-φd |

|||||||

75TSWA36-11.5*2 |

2 |

1241 |

177 |

180 |

250 |

535 |

1046 |

690 |

89 |

410 |

475 |

4-φ25 |

195 |

160 |

80 |

4-φ18 |

|||||

75TSWA36-11.5*3 |

3 |

1361 |

257 |

260 |

250 |

545 |

1046 |

690 |

128 |

410 |

475 |

4-φ25 |

195 |

160 |

80 |

4-φ18 |

|||||

75TSWA36-11.5*4 |

4 |

1526 |

337 |

340 |

250 |

545 |

1284 |

830 |

171 |

475 |

475 |

4-φ25 |

195 |

160 |

80 |

4-φ18 |

|||||

75TSWA36-11.5*5 |

5 |

1606 |

417 |

420 |

250 |

545 |

1284 |

830 |

211 |

475 |

475 |

4-φ25 |

195 |

160 |

80 |

4-φ18 |

|||||

75TSWA36-11.5*6 |

6 |

1731 |

497 |

500 |

250 |

545 |

1488 |

980 |

245 |

475 |

475 |

4-φ25 |

195 |

160 |

80 |

4-φ18 |

|||||

75TSWA36-11.5*7 |

7 |

1811 |

577 |

580 |

250 |

545 |

1488 |

980 |

245 |

475 |

475 |

4-φ25 |

195 |

160 |

80 |

4-φ18 |

|||||

75TSWA36-11.5*8 |

8 |

1916 |

657 |

660 |

250 |

560 |

1653 |

1150 |

239 |

480 |

480 |

4-φ25 |

195 |

160 |

80 |

4-φ18 |

|||||

75TSWA36-11.5*9 |

9 |

1996 |

737 |

740 |

250 |

560 |

1653 |

1150 |

239 |

480 |

480 |

4-φ25 |

195 |

160 |

80 |

4-φ18 |

|||||

75TSWA36-11.5*10 |

10 |

/ |

/ |

/ |

/ |

/ |

/ |

/ |

/ |

/ |

/ |

/ |

/ |

/ |

/ |

/ |

|||||

75TSWA36-11.5*11 |

11 |

/ |

/ |

/ |

/ |

/ |

/ |

/ |

/ |

/ |

/ |

/ |

/ |

/ |

/ |

/ |

|||||

model |

series |

Pump size (H2=B) |

Foot size |

Import and export flanges |

|||||||||||||||||

L |

L1 |

L2 |

B |

H3 |

L3 |

L4 |

L5 |

B1 |

B2 |

4-φb |

D |

D1 |

Dn |

n-φd |

|||||||

100TSWA69-15.6*2 |

2 |

1575 |

255 |

200 |

310 |

610 |

1322 |

900 |

100 |

505 |

505 |

4-φ30 |

230 |

190 |

100 |

8-φ23 |

|||||

100TSWA69-15.6*3 |

3 |

1720 |

355 |

300 |

310 |

610 |

1322 |

900 |

149 |

505 |

505 |

4-φ30 |

230 |

190 |

100 |

8-φ23 |

|||||

100TSWA69-15.6*4 |

4 |

1885 |

455 |

400 |

310 |

610 |

1463 |

975 |

200 |

505 |

505 |

4-φ30 |

230 |

190 |

100 |

8-φ23 |

|||||

100TSWA69-15.6*5 |

5 |

2050 |

555 |

500 |

310 |

620 |

1701 |

1240 |

202 |

525 |

525 |

4-φ30 |

230 |

190 |

100 |

8-φ23 |

|||||

100TSWA69-15.6*6 |

6 |

2150 |

655 |

600 |

310 |

620 |

1701 |

1240 |

157 |

525 |

525 |

4-φ30 |

230 |

190 |

100 |

8-φ23 |

|||||

100TSWA69-15.6*7 |

7 |

2295 |

755 |

700 |

310 |

630 |

1959 |

1450 |

198 |

565 |

565 |

4-φ30 |

230 |

190 |

100 |

8-φ23 |

|||||

100TSWA69-15.6*8 |

8 |

2420 |

855 |

800 |

310 |

640 |

1959 |

1450 |

199 |

565 |

565 |

4-φ30 |

230 |

190 |

100 |

8-φ23 |

|||||

100TSWA69-15.6*9 |

9 |

2520 |

955 |

900 |

310 |

640 |

2059 |

1550 |

199 |

565 |

565 |

4-φ30 |

230 |

190 |

100 |

8-φ23 |

|||||

100TSWA69-15.6*10 |

10 |

/ |

/ |

/ |

/ |

/ |

/ |

/ |

/ |

/ |

/ |

/ |

/ |

/ |

/ |

/ |

|||||

model |

series |

Pump size (H2=B) |

Foot size |

Import and export flanges |

|||||||||||||||||

L |

L1 |

L2 |

B |

H3 |

L3 |

L4 |

L5 |

B1 |

B2 |

4-φb |

D |

D1 |

Dn |

n-φd |

|||||||

125TSWA90-21.6*2 |

2 |

1740 |

270 |

205 |

320 |

670 |

1312 |

990 |

220 |

500 |

500 |

4-φ30 |

270 |

220 |

125 |

8-φ25 |

|||||

125TSWA90-21.6*3 |

3 |

1890 |

370 |

305 |

320 |

670 |

1449 |

1000 |

230 |

500 |

500 |

4-φ30 |

270 |

220 |

125 |

8-φ25 |

|||||

125TSWA90-21.6*4 |

4 |

2060 |

470 |

405 |

320 |

680 |

1603 |

1100 |

240 |

520 |

520 |

4-φ30 |

270 |

220 |

125 |

8-φ25 |

|||||

125TSWA90-21.6*5 |

5 |

2250 |

570 |

505 |

320 |

695 |

1774 |

1170 |

270 |

570 |

520 |

4-φ30 |

270 |

220 |

125 |

8-φ25 |

|||||

125TSWA90-21.6*6 |

6 |

2420 |

670 |

605 |

320 |

725 |

2005 |

1260 |

305 |

630 |

520 |

4-φ30 |

270 |

220 |

125 |

8-φ25 |

|||||

125TSWA90-21.6*7 |

7 |

2520 |

770 |

705 |

320 |

725 |

2005 |

1260 |

305 |

630 |

520 |

4-φ30 |

270 |

220 |

125 |

8-φ25 |

|||||

125TSWA90-21.6*8 |

8 |

2670 |

870 |

805 |

320 |

725 |

2243 |

1430 |

305 |

630 |

570 |

4-φ30 |

270 |

220 |

125 |

8-φ25 |

|||||

125TSWA90-21.6*9 |

9 |

2770 |

970 |

905 |

320 |

725 |

2243 |

1430 |

305 |

630 |

520 |

4-φ30 |

270 |

220 |

125 |

8-φ25 |

|||||

125TSWA90-21.6*10 |

10 |

/ |

/ |

/ |

/ |

/ |

/ |

/ |

/ |

/ |

/ |

/ |

/ |

/ |

/ |

/ |

|||||

model |

series |

Pump size (H2=B) |

Foot size |

Import and export flanges |

|||||||||||||||||

L |

L1 |

L2 |

B |

H3 |

L3 |

L4 |

L5 |

B1 |

B2 |

4-φb |

D |

D1 |

Dn |

n-φd |

|||||||

150TSWA155-30*2 |

2 |

1964 |

236 |

237 |

350 |

720 |

1437 |

1000 |

80 |

720 |

575 |

4-φ30 |

280 |

240 |

150 |

8-φ23 |

|||||

150TSWA155-30*3 |

3 |

2234 |

350 |

352 |

350 |

735 |

1735 |

1165 |

148 |

735 |

675 |

4-φ30 |

280 |

240 |

150 |

8-φ23 |

|||||

150TSWA155-30*4 |

4 |

2399 |

465 |

467 |

350 |

745 |

1922 |

1260 |

215 |

745 |

675 |

4-φ30 |

280 |

240 |

150 |

8-φ23 |

|||||

150TSWA155-30*5 |

5 |

2664 |

580 |

582 |

350 |

780 |

2129 |

1470 |

212 |

780 |

765 |

4-φ30 |

280 |

240 |

150 |

8-φ23 |

|||||

150TSWA155-30*6 |

6 |

2829 |

695 |

697 |

350 |

/ |

/ |

/ |

/ |

/ |

/ |

/ |

/ |

/ |

/ |

/ |

|||||

150TSWA155-30*7 |

7 |

2944 |

810 |

812 |

350 |

/ |

/ |

/ |

/ |

/ |

/ |

/ |

/ |

/ |

/ |

/ |

|||||

150TSWA155-30*8 |

8 |

3019 |

925 |

927 |

350 |

/ |

/ |

/ |

/ |

/ |

/ |

/ |

/ |

/ |

/ |

/ |

|||||

150TSWA155-30*9 |

9 |

3224 |

1040 |

1042 |

350 |

/ |

/ |

/ |

/ |

/ |

/ |

/ |

/ |

/ |

/ |

/ |

|||||

Installation instructions

(1) Preparation before installation:

1. Prepare installation tools and lifting equipment;

2. Check for any looseness or damage to the components of the water pump unit during transportation;

3. Check if the foundation is level.

(2) Installation sequence:

When the unit is transported to the site, the attached base has already calibrated the water pump and motor. When finding the flat base, it is not necessary to remove the water pump and motor, so installation is very convenient;

2. Place the base on the foundation and place wedge-shaped iron near the anchor screws. Raise the base by 20-40ram for leveling and filling with cement slurry;

3. Use a spirit level to check the levelness of the base. After leveling, fill the base with cement slurry and check the levelness again after the cement dries up;

When the power of the unit is high, the pump, motor, and base may be packaged separately for transportation convenience. In this case, the user needs to install and calibrate the water pump unit themselves. The method is as follows:

a、 Clean the dirt on the support plane of the base, the water pump foot, and the motor foot plane, and place the water pump and motor on the base;

b、 Adjust the level of the pump shaft, level it, and secure the water pump to the base with bolts to prevent movement;

c、 Lift the motor, align the pump coupling with the motor coupling, and lower the motor to the corresponding position on the base;

d、 Adjust the gap between the two couplings to about 5mm and calibrate whether the axis lines of the motor shaft and the pump shaft coincide. The method is to place a ruler on the coupling, and the outer circles of the two couplings should be level with the ruler. If they do not coincide, adjust the relative position of the motor or pump, or use a thin iron plate to adjust it;

e、 In order to check the installation accuracy, the gap between the two coupling planes should be measured with a feeler gauge at several different positions on the circumference of the coupling. The difference between the largest and smallest gaps on the coupling plane should not exceed 0.3mm, and the difference between the center lines of both ends should not exceed 0.1mm.

When the unit does not come with a base, it needs to be installed directly on the foundation using a method similar to 4, but more attention should be paid to calibration.

(3) Installation precautions:

1. During installation, the pipeline should not bear on the pump, otherwise it is easy to damage the water pump;

2. During installation, the anchor bolts must be tightened, and the unit should be inspected at regular intervals to prevent loosening, in order to avoid severe vibrations that may affect the performance of the pump during start-up and operation;

3. Before installing the water pump, carefully check whether there are any hard objects (such as stones, iron sand, etc.) in the pump flow channel that affect the operation of the water pump to avoid damaging the overcurrent components during the operation of the water pump;

4. For the convenience of maintenance and safety of use, a regulating valve should be installed on each inlet and outlet pipeline of the pump, and a pressure gauge should be installed on each inlet and outlet flange of the pump. For high lift pumps, to prevent water hammer, a check valve should also be installed before the outlet gate valve to cope with sudden power outages and other power loss accidents, so as to ensure that the pump operates under optimal conditions and extend its service life;

When the pump is used in suction applications, it should be equipped with a bottom valve, and the inlet pipeline should not have too many bends. At the same time, there should be no water or air leakage to avoid affecting the suction performance of the pump;

To prevent impurities from entering the pump and blocking the flow channel, a filter should be installed in front of the pump inlet to affect performance;

Before installing the pipeline, rotate the rotor components of the water pump without any friction sound or jamming phenomenon. Otherwise, the pump should be disassembled to check the cause;

8. The flanges of this series of pumps are designed according to the 2.5MPa specification, so the selection of pipeline flanges should match it.

Start, stop, and operate

1. Preparation before starting

1) When manually moving the rotor of the unit, it should rotate smoothly without any jamming or grinding.

2) Open the inlet valve Close the outlet valve And eliminate the air inside the pump Fill it with liquid;

3) Jogging motor Confirm if the steering is correct, otherwise the two phases in the wiring should be changed To change the direction of the motor

2. Start up and operation

1) Fully open the inlet valve and close the outlet pipeline valve;

2) Connect the power supply After the pump reaches normal speed, gradually open the valve on the discharge pipeline Adjust to the desired operating conditions:

3) Pay attention to the instrument reading Bearing temperature rise Its maximum temperature shall not exceed 75 ℃ and shall not exceed the external temperature of 35 ℃;

4) The normal degree of water leakage inside the packing room Based on 15 milliliters per minute The clamping force of the packing gland should be adjusted as needed:

5) If the pump experiences abnormal temperature rise, vibration, and noise during operation The vehicle should be stopped immediately to investigate the cause

3. Parking

1) Gradually close the valve on the discharge pipeline and cut off the power supply;

2) Close the inlet valve;

3) If the ambient temperature is below 0 ℃, the liquid inside the pump should be drained completely To prevent the water pump from freezing and cracking;

4) If it is discontinued for a long time The pump should be disassembled, cleaned, packaged and stored.

maintenance

1. The inlet pipeline must be highly sealed and not leak or leak.

2. It is prohibited to operate the pump for a long time under cavitation conditions;

3. It is prohibited to operate the pump under high flow conditions Long term operation of motor with overcurrent;

4. Regularly check the motor current value during pump operation Ensure that the pump operates within the range of 20 operating conditions;

5. The pump should be supervised by a dedicated person during operation to prevent accidents from occurring;

6. The pump should refuel the bearings every 500 hours of operation;

After long-term operation of the pump, due to mechanical wear and tear, the sound and vibration of the unit increase. It should be stopped for inspection, and if necessary, vulnerable parts and bearings can be replaced. The overhaul period of the unit is generally one year.

When there is a malfunction in the operation of the unit, it can be eliminated according to the methods provided in the table below. If it cannot be eliminated, do not disassemble the unit at will. Please contact our maintenance department or authorized maintenance point in a timely manner.

Common causes and solutions of malfunctions

fault |

reason |

solution |

| 1. The water pump does not absorb water, and the pointers of the pressure gauge and vacuum gauge jump violently. | a. Insufficient water injection into the water pump b. Air leakage in the inlet pipe and instrument |

a. Inject water into the water pump again b. Tighten the blockage at the leakage point |

| 2. The water pump does not absorb water, and the vacuum gauge shows a high vacuum level | a. The bottom valve is not open or blocked b. The resistance of the suction pipe is too high c. The water absorption height is too high |

a. Leveling or replacing the bottom valve b. Clean or replace the suction pipe c. Reduce water absorption height |

| 3. The pressure gauge is connected, but the water pump still does not produce water. | a. The resistance of the outlet pipe is too high b. The rotation direction is incorrect c. Impeller blockage d. Insufficient speed of water pump |

a. Clean or shorten the water pipe b. Check the rotation direction of the motor. c. Clean the impeller. d. Increase the speed of the water pump. |

| 4. The pump flow rate decreases or the head decreases. | a. Impeller or pipeline blockage b. Excessive wear on the sealing ring or impeller c. Insufficient rotational speed |

a. Clean the impeller and pipeline b. Replace damaged parts. c. Adjust to the rated speed. |

| 5. The power consumption of the water pump is too high. | a. The packing gland is too tight, causing the packing box to heat up b. Friction between impeller and sealing ring c. Excessive traffic |

a. Loosen the packing cap. b. Eliminate mechanical friction c. Turn down the outlet valve |

| 6. The internal sound of the water pump is abnormal, and the water pump cannot suction water. | a. Excessive resistance inside the suction pipe b. There is air leakage into the suction pipe c. Excessive flow leads to cavitation |

a. Reduce the suction height and shorten the length of the suction pipe b. Block the leakage point c. Adjust the outlet valve to operate the pump within the specified operating range |

| 7. The water pump vibrates severely. | a. Pump cavitation and impeller imbalance b. The pump shaft and motor are not on the same centerline c. Loose foundation bolts |

a. Eliminate cavitation and balance the impeller b. Coaxiality of the school water pump and motor c. Tighten the foundation bolts |

| 8. The bearing is overheated. | a. Insufficient or excessive lubricating oil, or deterioration b. The water pump and motor shaft are not concentric |

a. Check the oil level, clean the bearings and change the oil b. Align the axis centerline |